Plastic Resin & Polymers

Canada's plastic resin industry has become pivotal in global supply chains.

Due to their versatility and functionality, plastic resins and polymers are indispensable in various manufacturing processes, including packaging, automotive, electronics and everyday consumer products. These materials require precision handling to preserve their properties throughout the supply chain.

Canada's plastic resin industry has become pivotal in global supply chains and a leader in setting environmental benchmarks for the future of polymer manufacturing and logistics.

Resin Packaging Experts

Leveraging over 20 years of experience as a reliable logistics provider, the WTC team is invested in being your premier transloading partner for all of your resin needs.

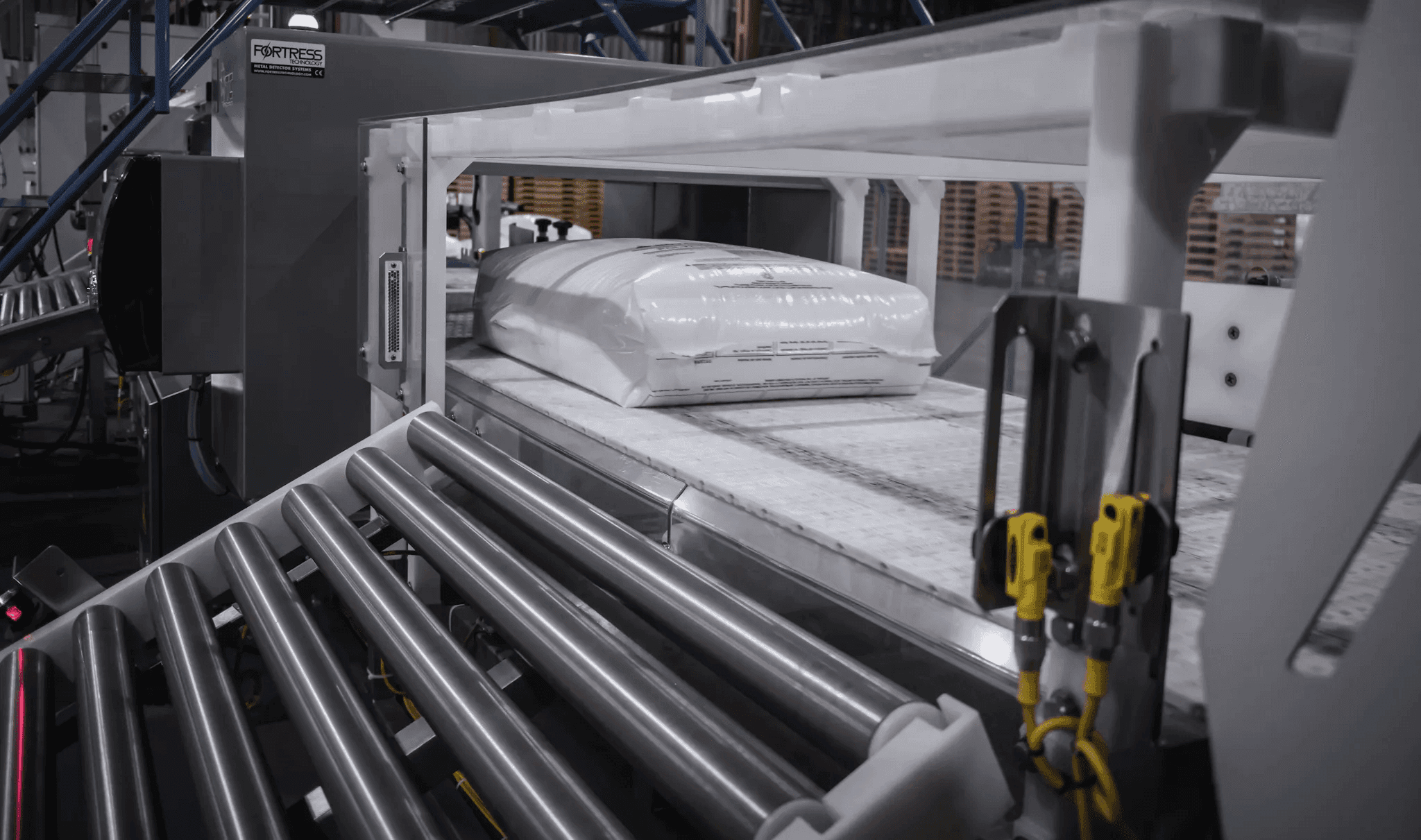

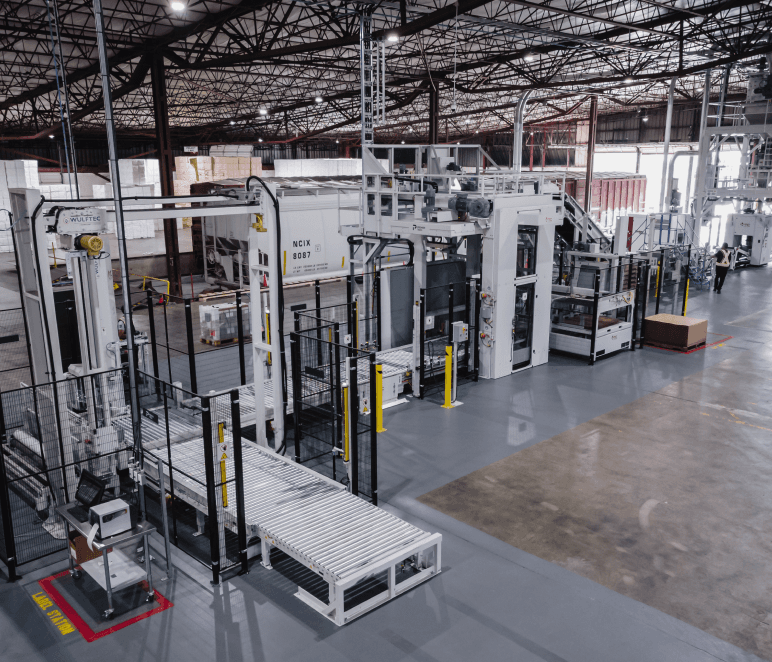

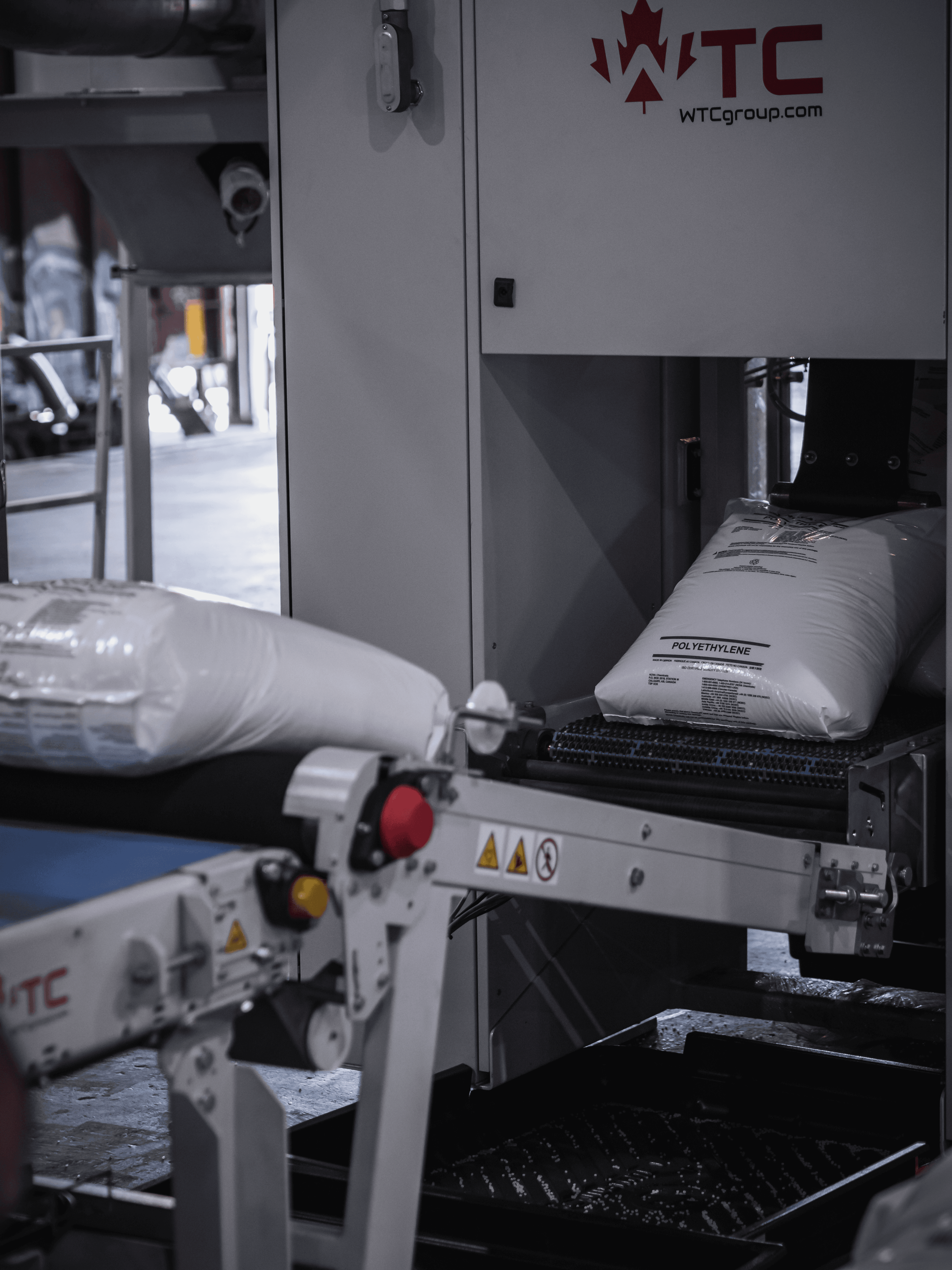

Quality Resin Bagging Lines

Our conveniently situated terminals feature multiple fully automated, state-of-the-art resin packaging lines. This advanced setup increases the bagged plastic resin throughput at the Port of Vancouver.

Proprietary Bagging Process

Leveraging advanced technology at every step, WTC revolutionizes resin transloading with a state-of-the-art resin bagging process designed for efficiency, quality, and safety.

Complete Export Services

In addition to packaging, palletization and container management, we handle every step of the export process including documentation, drayage and ocean freight.

Handling Resin

Transportation with Care

WTC Group's logistics services are tailored to the demanding requirements of transporting resin. We leverage cutting-edge logistics technology to enhance the efficiency of our operations and reduce the environmental impact of transporting these materials.

WTC is a proud member of Operation Clean Sweep and is committed to the highest environmental standards of handling resin and ultra-low emissions fleet operations.

Logistical Challenges

As the demand for resin and polymers increases worldwide, manufacturers face numerous logistical challenges in transporting raw materials. The most likely logistical challenges a resin or polymer producer will face include:

Temperature Sensitivity

Many plastic resins and polymers are sensitive to temperature fluctuations, which can alter their physical properties and render them unusable for precise manufacturing requirements. Logistical systems must ensure temperature-controlled environments during storage and transport.

Contamination Prevention

Preventing contamination of the resin or polymers is crucial. Impurities in the raw materials can significantly affect the quality and performance of the final products, requiring clean and secure handling facilities.

Regulatory Compliance

The resin and polymer industry faces stringent regulations concerning the production, handling, and disposal of materials. Compliance with international, national, and local regulations can complicate logistics planning and increase costs.

High Variability and Customization Needs

The diversity of plastic resins and polymers, each with specific attributes and applications, adds another layer of complexity. Producers often require customized logistic solutions to handle specific materials, especially when dealing with high-performance or specialty polymers critical for advanced applications in the automotive or electronics industries.